When it comes to flowmeters, there are some pretty hot opinions in the control and instrumentation world about the inaccuracies of an analog totalizer, and why using a pulse-driven counter/totalizer is the way to go.

After reading some really vicious web debates on the topic, I had the opportunity to test for myself, and I was surprised at how close the resulting totals were, and how insignificant the error was.

My test involved comparing a magnetic flowmeter’s internal totalizer to the totals calculated by a recorder from an analog output and a pulse output from the magmeter.

My test equipment and conditions

My test equipment and conditions

I generated the flow using a Siemens SITRANS Mag3100 flow tube, and attached the Mag6000 converter/transmitter for local display of the flow rate and total. The flow rate signal was output as a 4-20mA signal corresponding to a 0-10 GPM range. I configured the pulse output to trip every 0.25 gallons. The magmeter’s damping was set to the lowest value, 0.1, so the flow rate value and its 4-20mA jittered considerably with changing flow, as expected. The flow rate bounced from about 1.0 to about 2.9 gpm, throughout the test which lasted more than four hours.

Then, I connected a Honeywell eZTrend QXe paperless recorder. I took the flow rate signal and totalized it, tagging it on the screen as Analog Total. The magmeter pulses wired to the recorder’s digital input were counted and scaled, and tagged on the screen as Pulse Total. I configured the recorder’s analog input to sample at the 5GHz sample rate, on a scale of 0-10 GPM, with no averaging or damping applied to the flow rate signal.

Comparing the results

As I expected, the pulse total on the magmeter’s display and the Pulse Total on the recorder matched exactly.

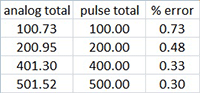

Then, I looked at the differences between the pulse total and the analog total. I took screen shots almost every 100 gallons (My apologies: I missed the 300 gallon screen shot because I was on a tech support call with a customer.)

The results were far closer than I’d been expecting, after reading all the bad press the analog flow totals had been getting.

The table here summarizes the error as a percentage of the pulse total value.

The table here summarizes the error as a percentage of the pulse total value.

The error, which never exceeded 1%, might be due to a minor calibration offset at the recorder’s 4-20mA input (or shunt resistor), and correctable with an analog calibration. The recorder was brand new, out-of-the-box, and I did not do a cal check on it prior to the test. If I had, I might have been able to calibrate out the minimal differences.

Next time, I want to do the same test with a couple seconds damping on the magmeter to see how that affects the error, given that factory default settings usually have damping enabled.

Related products:

Related posts:

- How many credits do I need for my Honeywell paperless recorder?

(Note: I used 10 credits to run this test: 6 for Events to do pulse, and 4 for analog totals.)

#1 by Eugene D Moe on October 25, 2022 - 6:00 pm

I had understood that there was a pulse totalized value such as 100 gallons per pulse. A flow rate would need to be calculated from that based on time duration and totalized flow value. Accuracy would improve over time. I was curious how error is affected by intermittent flow and scan rate of telemetry or PLCs for analog values. That is to say, what error comes from delayed recognition that flow started and delayed sense that it stopped over telemetry when hardware such as PLCs are used that don’t technically continuously monitor a value but take discrete snapshots of the value at each scan.

#2 by Angel Cardoza on October 9, 2019 - 1:01 pm

It’s been years since you wrote this but I’m finding it timely to my needs. I want to use the analog input on the EZ trend as you did to measure the gallons per minute and totalise that measurement. I’m struggling and was hoping that you had saved your programming steps to share. Or if you could point me to a helpful link. The water meter uses a 24 volt source to generate a 0.01 amp pulse. I am connecting it through the channel 1 analog input. Thanks!

#3 by danstips on October 9, 2019 - 2:28 pm

Angel-

Pulse is loosey goosey term.

Sometimes a pulse represents a given volume, (a volume pulse output) like one pulse every 1 gallon or 10 gallons. Other times, ‘pulse’ means the pulses in a frequency output, where the frequency is proportional to flow rate. An example would be a flow meter with a 0-4Kz frequency output where 1KHz is 25% of the max flow rate, 2KHz is 50% of the max flow rate.

A pulse output is not compatible with a Trendview analog input. A frequency (rate) pulse output needs a digital input (DI) card which can convert the pulses to a flow rate value like gallons per second or gallons per minute). A volume pulse output needs a DI card (extension board) and 3 credits (to enable “counters”) so that the pulses can be counted (summed).

The EZTrend’s DI card can handle frequency (rate) pulses up to 1,000 pulses per second (1KHz). Mini or MultiTrend recorders can use a different frequency input card that can handle up to 25KHz.

This is a project

– A DI card is an option on the EZTrend, but requires an extension card (if not already there, which is not likely).

– Be warned that getting a pulse output functioning with a recorder DI is 10 times the work of getting an analog output functioning with a recorder analog input.

– Unless you have unused firmware credits available on your recorder, you’d need to add more.

– The rate signal needs to be totalized. A totalizer is a credit enabled option, and to be useful, the total value needs its own “extra” pen

– volume pulses need to be summed, which requires a counter.

#4 by Kyle Chase on April 19, 2012 - 10:48 pm

That is a huge error, and will cost your client a lot of money. For example, we have a plant that runs roughly 400000 m3 of oil a year. If you convert that to barrels, that is 2515924.31 barrels. With an overage error of 0.46% (from your numbers), that would be an error of 11573.25 barrels, in your clients favour. With the current price of oil being $102.59/bbl, that would put your error as $1,187,299.90, which might make someone freak out, either your client, or their client. Not a risk anyone should be taking. Mind you, if its not for custody transfer, this might be fine.

#5 by danstips on April 20, 2012 - 2:28 pm

You make a good point, Kyle. It’s always important to consider the media and what level of accuracy is required for the application. Custody transfer apps tend to run closer to the 0.1% range, and in that case, the difference would be substantial. In my experiment, I wasn’t looking at a particular application, like the one you described, and my flowing water was significantly less costly than oil.

I was just curious as to exactly what kind of error I’d see, and whether that’s really enough to tell customers they had to use pulse input totalization, or avoid analog totalization at all costs. In some applications, that accuracy level would be sufficient. But it’s a question to be asked on the individual application level.

#6 by Angel Cardoza on October 9, 2019 - 3:07 pm

Is there a pulse counting device with a recording function that is more readily adapted to calculating and recording a totalized flow? Available through Lesman?